Normet

Developing a complete system for demanding underground operations

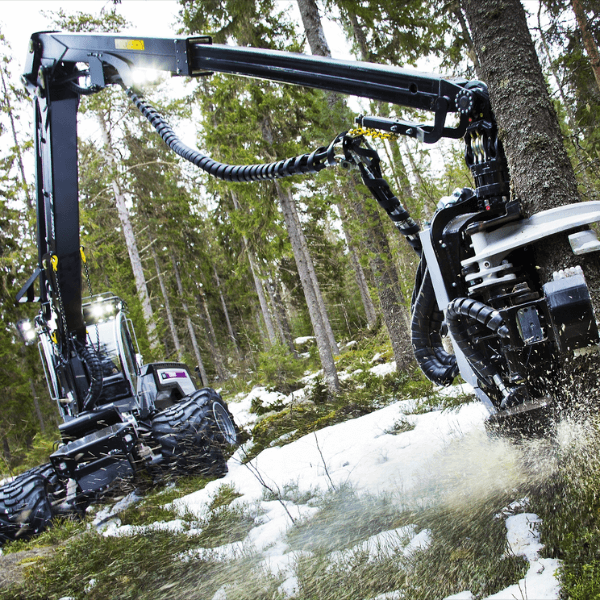

Normet is a growing and forward-thinking technology company focused on the future of underground operations. The company provides safe, sustainable, and efficient end-to-end solutions for various processes in underground mining, tunnelling, and civil construction.

Exertus has forged a strong and enduring partnership with Normet for over two decades. We have designed control systems for various machine types in demanding underground operations. The solutions have been constructed from different combinations of Exertus standard products and technologies.

“The control system that Exertus provides is now an essential part of our machines. It’s an enabler for advanced machines and processes. We’ve grown and evolved together during this partnership, which has been a valuable journey for both parties.” – Samu Kukkonen, Technology Director, Normet.

Partnership evolution: A need for more advanced control systems

Exertus and Normet’s history dates to the mid-2000s. The collaboration began when Normet needed a more advanced control system for their machines. The machines were hydraulically and electrically controlled then, but more sophisticated functions required new technology.

The partnership has evolved significantly over nearly 20 years. First, Exertus offered comprehensive software development services, but as Normet’s internal expertise grew, the collaboration adapted to a new form.

“The collaboration with Exertus has not been just transactional but rather a co-innovation partnership where we develop solutions together. This collaboration requires openness and trust.”– Samu Kukkonen, Technology Director, Normet.

Today, Normet leads the software development while Exertus functions as an essential part of the team. The collaboration has evolved from a fast-paced initial phase into more organized processes and larger teams, fostering the development of both companies.

Integrated control system solutions

Normet manufactures a wide variety of machinery, including individual pieces tailored to the needs of its customers. Therefore, the workload associated with designing control systems for various machines must be manageable.

An integration was developed between Exertus’ control system design environment and Normet’s electrical design tools as a solution. When the electrical schematic of a machine control system is generated directly from the machine electrical schematics, and the programming environment receives the necessary information automatically, the processed data can be efficiently reused.

The foundation of this process is modular software design, which incorporates all the features developed up to that point and enables efficient product-specific variation.

As part of the collaboration, we developed a concept for simulators where selected physical components of the system can be replaced with virtual counterparts – digital twins – enabling flexible and scalable training setups. In the lightest configuration, the simulator could even fit into a small briefcase. To facilitate remote monitoring and maintenance of the machines, Normet also utilizes Exertus’ technologies for two-way IoT connections and edge computing, ensuring that the volume of data transferred remains manageable.

“Exertus has been essential in fully electric machines, advanced shotcrete functions, automation solutions, and data collection for industrial internet solutions.” Samu Kukkonen, Technology Director, Normet.

Addressing underground challenges

Normet’s machines are deployed in the most demanding underground operating conditions. In these environments, water dripping onto equipment causes severe corrosion, necessitating extensive maintenance. At the same time, connections to the surface have traditionally been very weak or nonexistent.

“Our machines operate in extremely challenging environments, often hundreds of meters underground where connectivity is limited. The self-diagnostics and operational guidance that Exertus has built into the control systems are crucial for maintaining efficiency and safety in these conditions.” Samu Kukkonen, Technology Director, Normet

Given these challenges, we have focused from the very beginning on developing top-notch self-diagnostics for the machines.

Another priority has also been the operational guidance of the machinery. For instance, the machine indicates what is hindering the user’s requested action from being executed, an important feature that enhances user safety and system reliability.

Business benefits and applications

The control systems from Exertus have assisted Normet in developing solutions that meet current market demands. These systems have enabled Normet to satisfy customer expectations for advanced functionality in underground mining equipment.

Applications of the solutions developed with Exertus include, for example:

- An ANFO explosive dosing system

- A concrete pumping and accelerator dosing system for shotcrete machines

- An emulsion explosive manufacturing and dosing system

- A control system for personnel lifters

- Control system algorithms for hydrodynamic, hydrostatic, and electric power transmissions

Learn more about Normet: normet.com.

”Over the years, the partnership with Normet has also introduced positive challenges, inspiring our team to deliver their best. The cooperation has been seamless and productive, and together, we have developed a high-quality system suitable for underground operations worldwide. User safety has always remained a top priority, even though the system has adapted flexibly to different delivery requirements.”

Sami Loukasmäki

Chief System Architect, Co-Founder, Exertus Oy